How to Select the Right Screw Jack for Your Application?

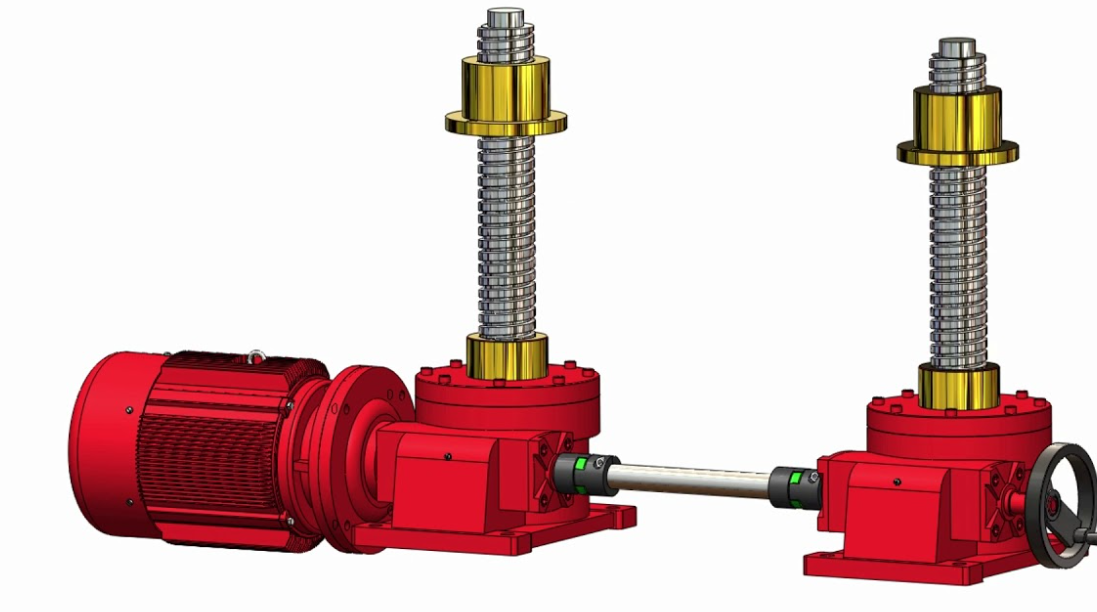

Selecting an effective screw jack is essential to designing an efficient motion system. Care must be taken when selecting the suitable model based on application constraints, such as load capacity, duty cycle, horsepower output, column strength requirements and critical speed requirements.

These design factors will determine the most cost-effective and energy-efficient jack, such as for static loads with duty cycles under 25%; typically a machine screw jack would be the optimal solution in these instances.

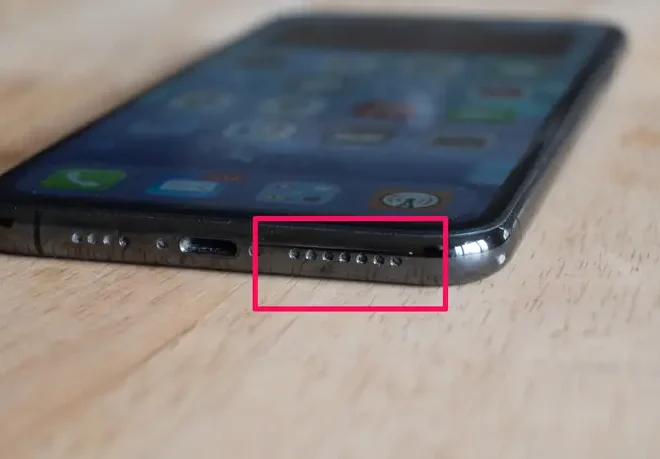

Load Capacity

A screw jack’s load capacity refers to how much it can lift at one time, making it a key consideration when choosing the appropriate model for your application.

Capacity for screw materials and critical speeds will also play an integral part in this calculation.

Length is also an influential factor. Longer screws tend to have lower column strength and thus are limited in their capacity to support compressive loads.

As well as your load capacity, other aspects of your application must also be taken into consideration, including travel rate, critical speed and number of jacks required.

Similarly, linear motion systems require jacks with both thrust and guidance support; selecting the ideal jack will enable you to gain all the features necessary to safely move your machine efficiently and safely. Nook Industries’ team of engineers are also on standby should any assistance be required!

Speed

Speed of a screw jack is often taken for granted; however, this factor should never be neglected when selecting an ideal screw jack for any application. When making your decision it is vital that you consider this element carefully.

The maximum possible operating speed of a screw jack depends on its thread size, pitch and rotation ratio of its worm gear worm gear. This factor should be taken into consideration when choosing an ideal screw jack for your application as its selection has an effect on drive torque requirements and travel speeds that could influence energy efficiency.

Translation speed of a screw jack is determined by how often its lead screw spindle starts up. Single start screw jacks tend to self-lock as their friction angle exceeds helix angle – no axial force is needed to turn them. Multi start screws may require higher starting torques for successful operation.

Duty Cycle

Duty Cycle When selecting a screw jack, duty cycle is an important factor that can greatly influence its selection process. As more often or quickly the load is moved, its duty cycle increases.

Ball screw jacks are typically the superior solution when it comes to load with higher duty cycles, as their efficiency exceeds bevel gear and worm gear jacks by up to 50 percent compared with bevel gear and worm gear jacks, providing great efficiency and positional accuracy at higher speeds.

Screw jack load capacities are determined by its drive sleeve, lift shaft and bearings. All anticipated loads must be calculated carefully to meet its rated capacity of the jack.

Gearing

Gearing of a screw jack – typically either worm gears or bevel gears – has a profound impact on linear motion system selection, including load capacity (static, dynamic, moving acceleration/deceleration/cutting) as well as duty cycle considerations.

Note that physical constraints posed by drive sleeve, lift shaft and bearings limit how much force can be applied to a screw jack. Therefore, you should calculate anticipated loads accurately to ensure they fall within its rated load capacity.

As part of this research, several characterization tests were conducted to better understand how a screw jack responds in dynamic loading environments, including step loads and time-varying square wave inputs to it.

Pulling screw jacks are a type of mechanical screw jack that is specifically designed for applications where a pulling force is required. These types of screw jacks are commonly used in applications such as tensioning wires or cables, adjusting the position of heavy machinery, or lifting and lowering heavy loads.

When selecting a pulling screw jack for your application, there are several factors that should be taken into consideration. One important factor is the maximum load capacity of the screw jack. It’s essential to choose a screw jack that can handle the weight of the load being pulled without compromising its structural integrity.

Another critical consideration is the required speed and precision of the screw jack. Some pulling screw jacks can provide quick and efficient pulling, while others offer slower, more controlled movements. The level of precision required will depend on the specific application, with some applications requiring very precise movements to avoid damage or injury.

It’s also important to consider the environment in which the pulling screw jack will be used. Factors such as temperature, humidity, and exposure to harsh chemicals or other substances can impact the performance of the screw jack over time.

Finally, it’s crucial to consider the mounting requirements and available space for the screw jack. Pulling screw jacks may require specific mounting configurations or additional hardware for optimal performance.

Overall, selecting the right pulling screw jacks for your application requires careful consideration of these various factors to ensure that you choose the best possible option for your needs.