Mechanical Lifting Solutions: Screw Jacks vs. Hydraulic Systems

When it comes to industrial lifting applications, two primary contenders emerge: screw jacks and hydraulic systems. Both offer distinct advantages and disadvantages, making the choice dependent on specific project requirements. Let’s delve into the key characteristics of each system to guide you in selecting the optimal lifting solution.

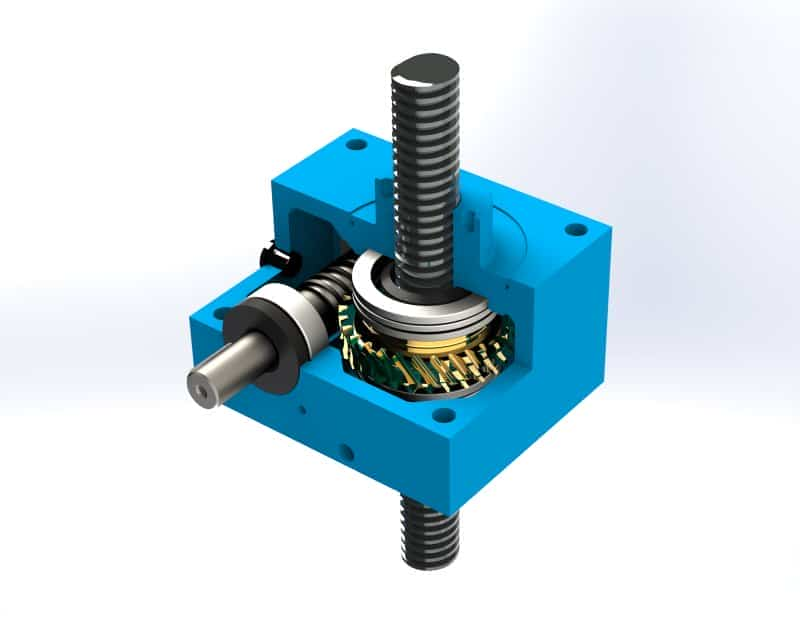

Screw Jacks:

The Power of Simplicity:

- Mechanism: Screw jacks utilize a threaded screw and nut mechanism, converting rotary motion into linear lifting or pushing force.

- Advantages: Simple and robust design, offering high load capacity, precise control, and self-locking ability in certain types. They require minimal maintenance and are generally less expensive than hydraulic systems.

- Disadvantages: Slower lifting speeds compared to hydraulics and limited lifting heights depending on the screw lead. Friction can lead to heat generation during extended operation.

Hydraulic Systems:

Speed and Force at a Price:

- Mechanism: Hydraulic systems rely on pressurized fluid to generate linear motion through pistons and cylinders.

- Advantages: Offer high lifting speeds, long lifting strokes, and the ability to handle very heavy loads. They provide smooth and controllable operation.

- Disadvantages: Hydraulic systems are generally more complex and expensive than screw jacks. They require maintenance for proper fluid levels and potential leakages. The reliance on pressurized fluids introduces safety considerations.

Choosing the Right Lifting Solution:

Here are some key factors to consider when selecting between screw jacks and hydraulic systems:

- Load Capacity: Both systems can handle substantial loads, but hydraulics excel for extremely heavy lifting tasks.

- Lifting Speed and Height: If speed and extended lifting distances are crucial, hydraulics are the better option.

- Precision Control: Screw jacks offer exceptional precision for precise positioning requirements.

- Cost and Maintenance: Screw jacks are generally more cost-effective and require less maintenance.

- Environmental Considerations: Hydraulics might be less suitable for dusty or dirty environments due to potential contamination concerns.

For more information on screw jack design and material selection, you can visit MechJacks https://mechjacks.com/en/. MechJacks is a leading manufacturer of high-quality screw jacks, offering a wide range of options to suit various industrial applications.

Conclusion:

Screw jacks and hydraulic systems are valuable tools for industrial lifting applications, each catering to specific needs. For projects requiring high load capacity, precise control, and simplicity, screw jacks shine. Hydraulic systems are ideal for situations demanding high lifting speeds, long strokes, and the ability to handle immense weight. By carefully evaluating your project requirements, you can make an informed choice and leverage the optimal lifting solution for success.